PRO/CESS

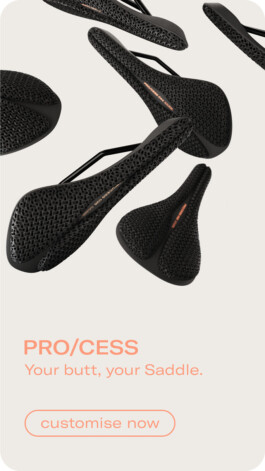

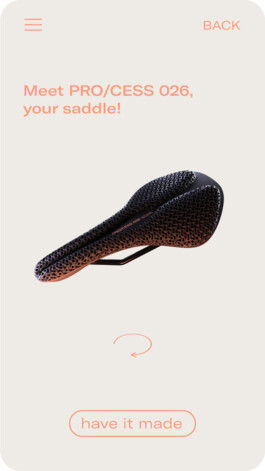

PRO/CESS is a gender-sensitive, fully customised and additively manufactured bike seat. In contrast to determined products, the concept embraces an open source process that focuses on the particular needs of users and rejects gendered standards.

scroll or find the concept paper here

Concept

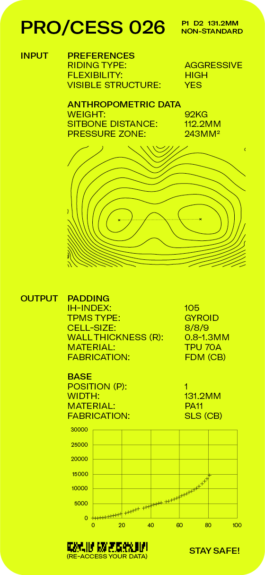

The process follows the principle of input/algorithm/output. The input is formed by the individual data of the users, which is gathered decentrally with an app. Utalising simple image recognition technology, a 3D model of the butt is created. Corresponding ergonomic data is then derived and additional preferences are entered.

Based on this, the algorithm adjusts the shape, size, padding and look of the saddle in the CAD model and is constantly optimised with new data sets. Print data for FDM and SLS printing is then generated and made available as output.

Finally, users have the choice of printing the saddle themselves, sharing the order in the maker community or ordering the saddle from a microfactory.

In addition to the individual product, the process focuses on participation and flexibility. It is fluid in its form and can react agilely to feedback and external influences. In this way, standards of gender differentiation become obsolete and non-binary, empowering perspectives are present instead.

Design

research

Why do most products associate ergonomics with gender?

Ergonomics standards are frequently created based on the gender binary – ignoring a lack of factual accuracy and failing to reflect human diversity. Market differentiation strategies that draw supposed conclusions from large statistical data in fact turn out to be inappropriate on an individual level. Further, many products are designed with the assumption of the male body as norm, with female versions often considered as a variation, thus reinforcing binary gender perceptions and patriarchal power structures.

A database of butts

To investigate the relationship between gender and design, a field study was conducted, and the Instagram community was asked to provide their butt imprints. The data was collected in compliance with data protection regulations and fed into an algorithm to generate 3D models and derive comparable parameters. The study analyzed more than 40 butt imprints, and the results showed that there is a wide range of butt geometries. The most relevant factor in determining ergonomic design - the distance between the sitbones or ischial tuberosity - could not be separated based on gender. This research demonstrates that gender-sensitive design is a viable concept.

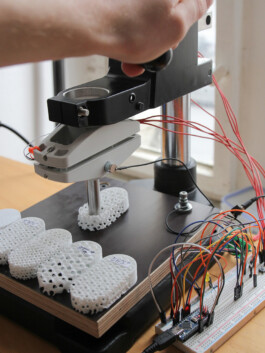

Low barrier data capture

The decentralized data collection is the basis for meeting the demand of accessibility and individual needs orientation of a gender-sensitive design process. Conventional saddle fitting procedures, in which customers have to visit specialized stores or pay for the measurement of anthropometric data, are therefore out of the question. Instead, a resource-saving process was developed that works completely independently via an app and uses simple computer vision technologies to generate a precise 3D imprint of the buttocks.

Structure from Motion is an image recognition process that uses two-dimensional images to create a three-dimensional point cloud of the imaged surface relief. To do this, distinctive keypoints are identified in the image material and related to one another. Together with information about the focal length and sensor size of the camera, the respective distance between sensor and keypoint can be calculated in the next step, and the latter can finally be displayed as a 3D point cloud.

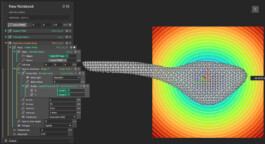

Field driven TPMS-Structures

Additive manufacturing enables precisely controllable volume structures to further develop conventional paddings. The cell size of the gyroid structure is used to determine the density and thus the general indentation hardness of the padding as a function of weight and seat position. For the comfort zones in the ischial tuberosities and pubic tuberosities, the cell size is adjusted with the use of so-called field-driven ramps.

MATERIAL STUDY

PROTOTYPE